Visual tests VT

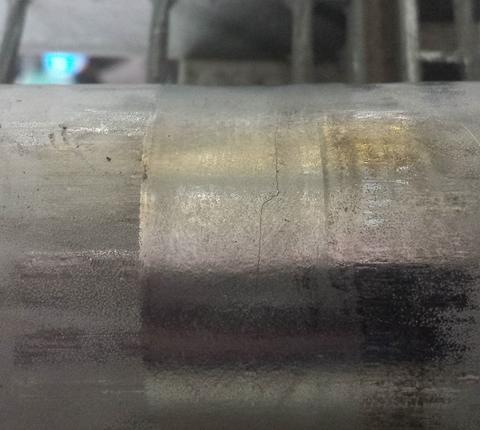

This is the oldest and most common method of control, but still with very large possibilities. Visual testing is an indispensable element in every manufacturing and operation process. The visual method is indispensable at all stages of the production of welded joints starting from the preparation of elements before welding, through inter-operative control to the acceptance of finished welds.

Visual tests can be divided into: - direct visual tests, - remote visual tests. Direct tests are performed with the unaided eye or with the use of magnifiers with low magnification. Additional equipment also includes such devices as weld gauges, feeler gauges, sets of mirrors, additional light sources, etc. Remote visual tests are the basic method in the study of areas difficult to access and as a preliminary assessment of the examined elements.

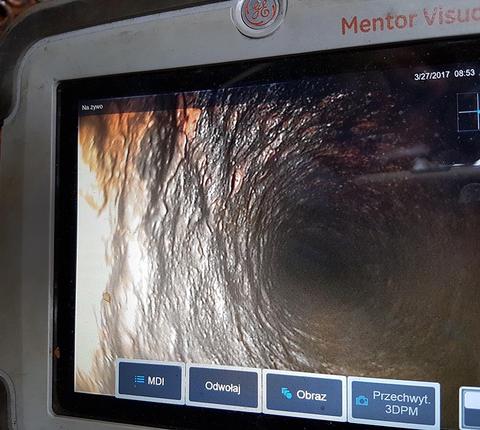

Such tests are carried out using specialized optical devices, such as sets of mirrors, fiberscopes, borescopes, and in particular videoendoscopes enabling image recording. These devices allow to test hard-to-reach places, elements with complex shapes, such as elements of engines, pipelines, valves, etc., often where it is impossible to apply other non-destructive testing methods.

Modern equipment from the world's leading manufacturers enables the recording of images and film files of very high quality and resolution, as well as measurements of detected non-conformities of the tested elements.